Introduction

This application note highlights the considerations faced in mounting and operating Nanomotion motors. By following these guidelines, smooth installation and mounting will be achieved, maximizing the motor’s unique features.

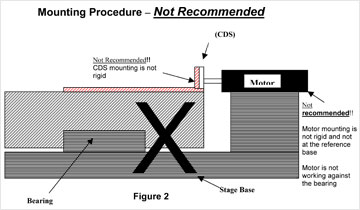

Mounting

The mounting base and the method used for mounting the motor should facilitate high stiffness and resonant frequencies, affecting the system’s overall accuracy.

The motor mounting base and the Ceramic Drive Strip (CDS) mounting fixture should be rigid. Avoid the use of cantilevers for the mounting.