Introduction

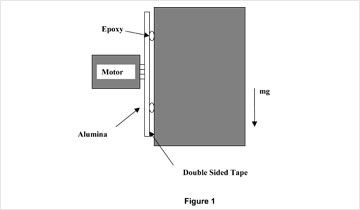

The intrinsic friction of the Nanomotion motor offers an interesting solution for Z applications, where gravity functions as a permanent load. Nevertheless, some considerations must be taken into account to ensure safe and reliable system operation. This report highlights these considerations and shows that in order to achieve successful implementation in Z direction the load should not exceed 1/3 of the nominal static holding force.