Introduction

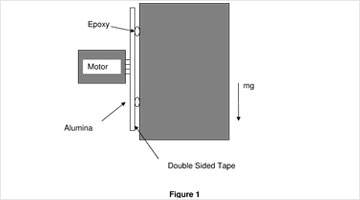

The intrinsic friction of the Nanomotion motor offers an interesting solution for Z applications, where gravity functions as a permanent load. Nevertheless, some considerations must be taken into account to assure safe and reliable system operation. This report highlights these considerations in order to assure successful implementation.